Discover Our Plate Heat Exchanger Cleaning Services

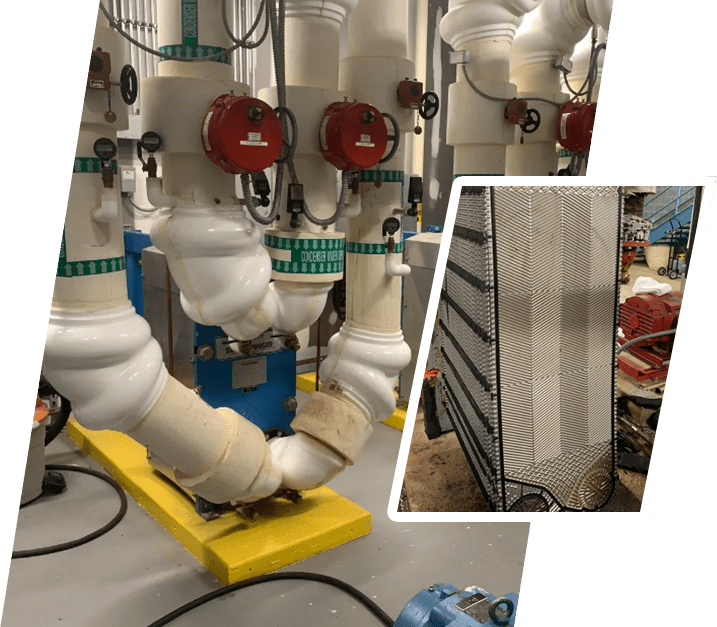

Heat Exchanger Cleaning – Crystal Clear MCS provides on-site plate and frame heat exchanger cleaning for all types and models of exchangers. This process includes opening the unit, cleaning each plate individually, inspecting all gaskets and plates for serviceability and returning the unit to operation. This cleaning is designed to reduce pump pressure and increase heat transfer, resulting in energy savings recommended by the manufacturer.

- HVAC equipment makes up over 50% of a facility's energy cost, and if not cleaned and maintained on a regular basis, it can cost the owners thousands of $$$$ every year.

- One degree variance in the manufacturer set up, due to fouling, costs on average $15.00 per hour for every hour the unit operates. Running 8 hours a day, 5 days a week, adds up to $600.00 per week in lost energy.

Today, given escalating energy prices, every component in a system’s operation must have validation of its energy efficiency.

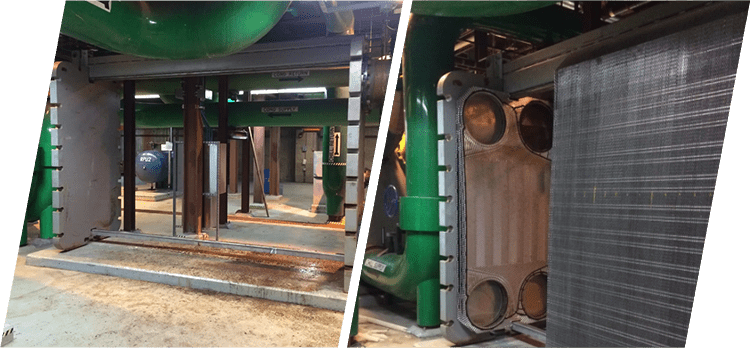

If a water line has restricted flow due to scale, debris, or corrosion, undue strain is put on the pump. This causes systems to malfunction due to overheating. It also reduces the life of the equipment, causing lost $$$$ in performance and energy.

Crystal Clear MCS can set up maintenance schedules such as cleaning, gasket replacement, plate pack refurbishment or replacement of the entire unit. We also sell parts for all makes and models.

Onsite Closed System CHEMICAL Cleaning

- Why Onsite Chemical cleaning should be your last option.

- Without opening and inspecting the exchanger you do not know what is inside of it.

- Without knowing what is inside of it you don’t know what chemical to use to clean it.

- Chemical cleaning does nothing for organic material such as Dirt, Bugs, Pollen, Ect.

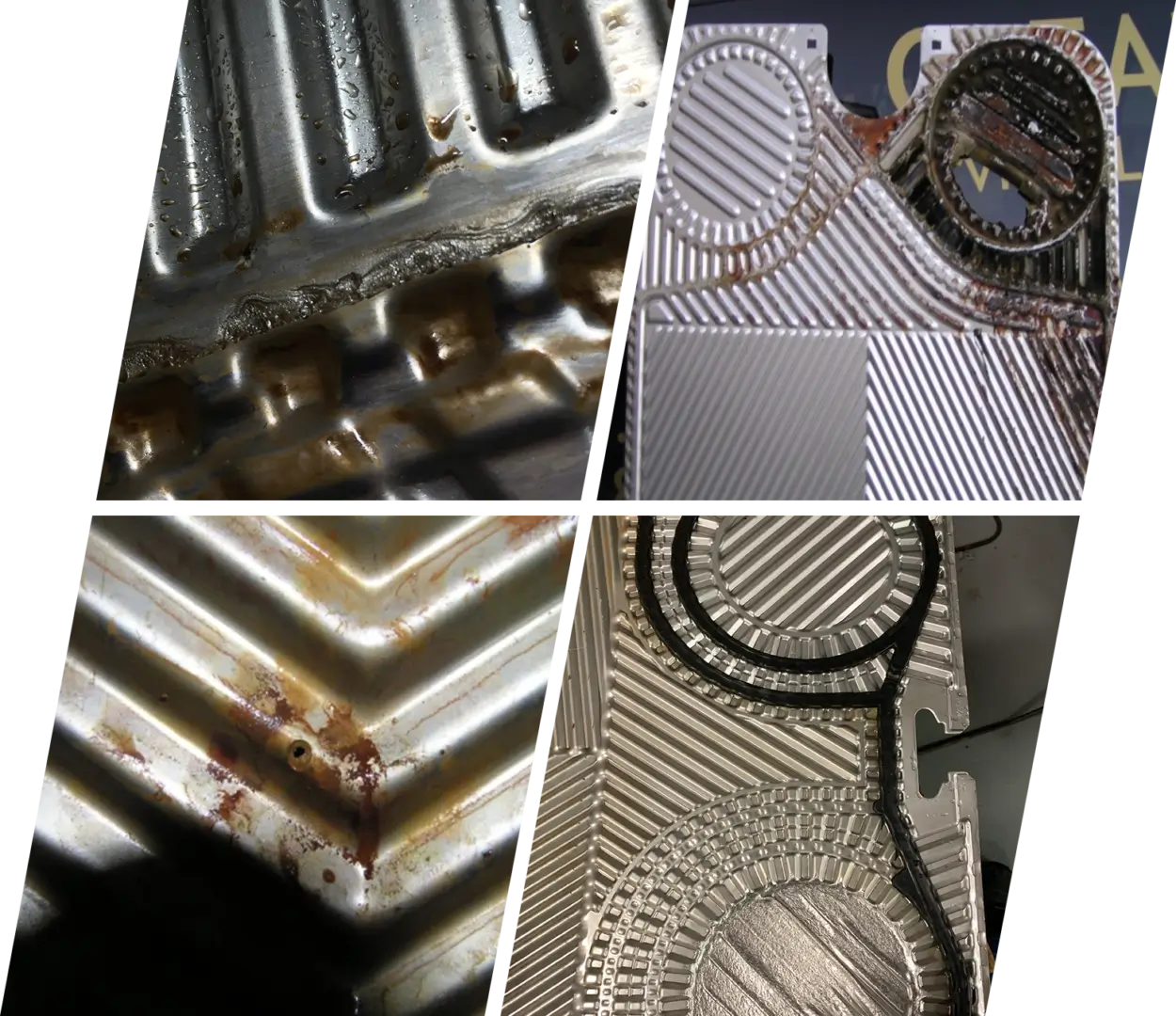

- The pictures to the right show what you don’t see with Closed System Cleaning.

- Acid Cleaning can damage your system by uncovering holes in your plates causing cross contamination in your system.

- If you have any concerns or would like a 2nd set of eyes to review your water treatment program, Crystal Clear MCS recommends Nalco Water an Ecolab Company, please click below to visit their website.

Open Unit MANUAL Cleaning

- Done on-site and typically takes less than 8 hours to complete

- Removes 100% of the plate fouling and can be verified visually

- Will improve energy efficiency and reduce equipment failure and downtime

- Allows for a visual inspection of the entire unit before and after cleaning

- General cleaning can be accomplished without harsh and sometimes dangerous chemicals

- Lets you determine if parts must be replaced due to failure or poor chemical treatment

- Eliminates total plate pack replacement if not needed!

The chemical technique requires a water analysis to be completed before and after cleaning to determine which chemical should be used and to make sure it is completely removed when finished. This technique can require the use of 2 or more chemicals based on the condition of both sides of each plate, taking additional time to complete the project. When chemically cleaning an exchanger, the amount of time it takes will be determined by the amount of fouling within it.

Without opening and inspecting the exchanger, the actual amount of fouling is strictly guesswork. Part of a thorough cleaning is inspecting the unit for damage. i.e. compression fractures, perforations, rust and bad gaskets. If any of the plates have holes in them, there will be system water mixing with cooling water, which could damage the entire system.

This can only be accomplished using the open unit MANUAL cleaning technique.

The bottom line! It is better to open, inspect and then clean a plate and frame heat exchanger!

Your choice is Crystal Clear.